Walnut Drop-down Table

published on

Overview

- Made for a small kitchen

- Seats four

- Wall mounted and folds down

- Dual support arms are spring loaded; they push into place as the table is lifted

Lumber Selection and Glue-up

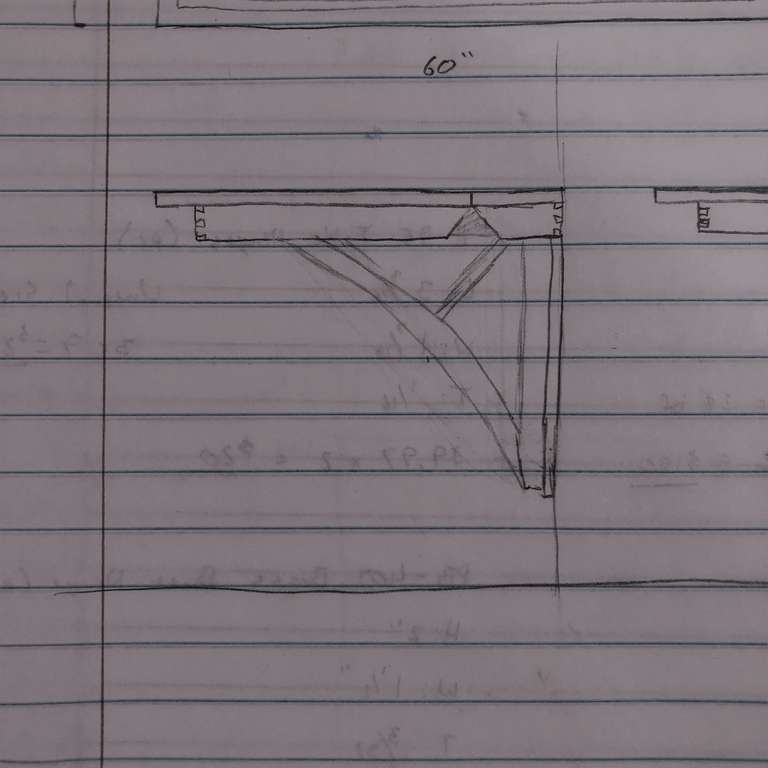

- Every project starts with a need and a rough sketch to caputre some ideas.

- Not all ideas survive scrutiny.

- The hinges are unlacquered with a slightly oxidised finish; a little wax stabilizes it.

- Jointing the edges for a tight fit for glue-up done by hand.

Fold-down Action

Video 1: Testing the fit of the apron when the table folds down.

Video 2: Spring-loaded table supports

Small Details

- The support arms are held back with small brass ball catches until the table is ready to be lifted.

- Torsion springs push the supports into place. The hinges are offset so oppposing screws don't collide.

- Half-lap joints create a mechanical interlock.

- Brass machine screws allow fine adjustments to level the table top.

The Finished Table

- The color was custom matched to a flooring sample for the customer.

- A process of shellac, dye, oil stain, and polyurethane offered a good match.